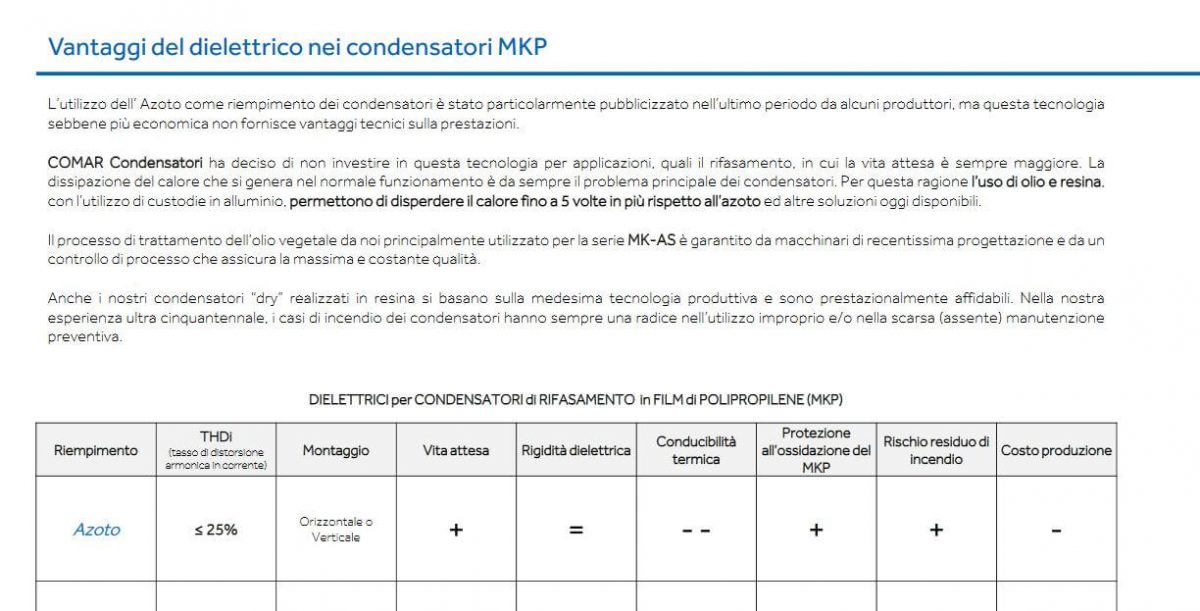

The use of nitrogen as filler of the condensers has been particularly publicized in the last period by some manufacturers, but this technology, although cheaper, does not provide technical benefits on performance.

COMAR Condensatori has decided not to invest in this technology for applications, such as power factor correction, in which the expected life is always greater. The dissipation of heat generated in normal operation has always been the main problem of the capacitors. For this reason the use of oil and resin, with the use of aluminium housings, allow to disperse heat up to 5 times more than nitrogen and other solutions available today.

The vegetable oil treatment process we mainly use for the MK-AS series is guaranteed by very recently designed machinery and by a process control that ensures maximum and constant quality.

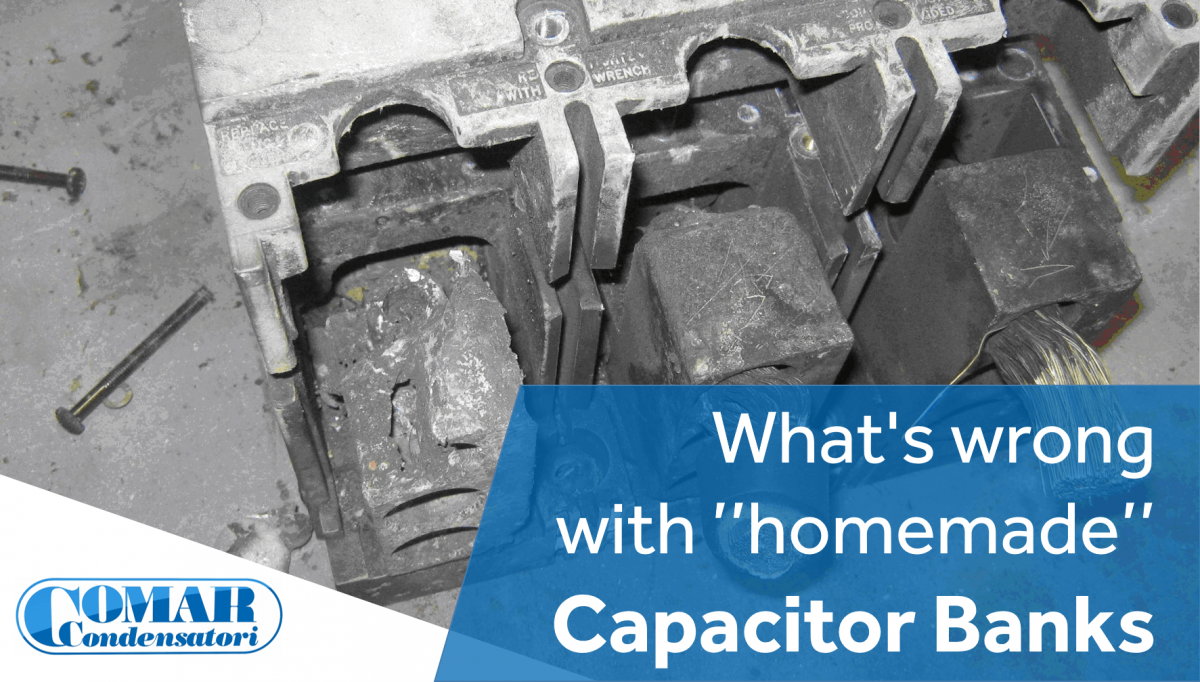

Even our resin “dry” capacitors are based on the same production technology and are highly reliable. In our over fifty-year experience, condenser fire cases are always rooted in improper use and / or in the scarce (absent) preventive maintenance.

DIELECTRIC FOR P.F.C. CAPACITORS in POLYPROPYLENE FILM (MKP)

| Filler | THDi (harmonic distortion rate in current) | Assembly | Expected life | Dielectric strength | Thermal conductivity | MKP oxidation prevention | Fire risk | Manuf.g cost |

|---|---|---|---|---|---|---|---|---|

| Nitrogen | ≤ 25% | Horizontal or Vertical | + | = | — | + | + | – |

| Vegetable Oil | ≤ 40% | Vertical | ++ | +++ | +++ | ++ | ++ | + |

| Resin | ≤ 40% | Horizontal or Vertical | ++ | ++ | ++ | +++ | + | ++ |

Regarding thermal conductivity:

| Filler | Thermal conductivity |

|---|---|

| Nitrogen | Low heat dissipation with MKP elements overheating |

| Vegetable Oil | Excellent heat dissipation from the MKP elements |

| Resin | Good heat dissipation from the MKP elements |

Regarding the oxidation prevention:

| Filler | Oxidation prevention of MKP |

|---|---|

| Nitrogen | Difficulty assessing the nitrogen content in the capacitor. Risk of leakage due to micro punctures or cracks |

| Vegetable Oil | Content of water vapor/ oxygen in the oil is controlled |

| Resin | The gel / semisolid matrix blocks oxidizing agents |

Regarding the residual fire risk:

| Filler | Residual fire risk |

|---|---|

| Nitrogen | Flammability of polypropylene |

| Vegetable Oil | Oil vapors are flammable at temperatures> 185 ° C |

| Resin | Flammability of polypropylene |

This is why COMAR Condensatori has decided not to use nitrogen as a dielectric, albeit cheaper, as it does not provide technical advantages over

performance.