COMAR Condensatori often receives requests for capacitors and components from electrical assemblers who want to build P.F.C. equipment independently. We always advise against pursuing this path as we are not worried about the competition (there is room for everyone!), but about the safety and reliability ofthis type of solution.

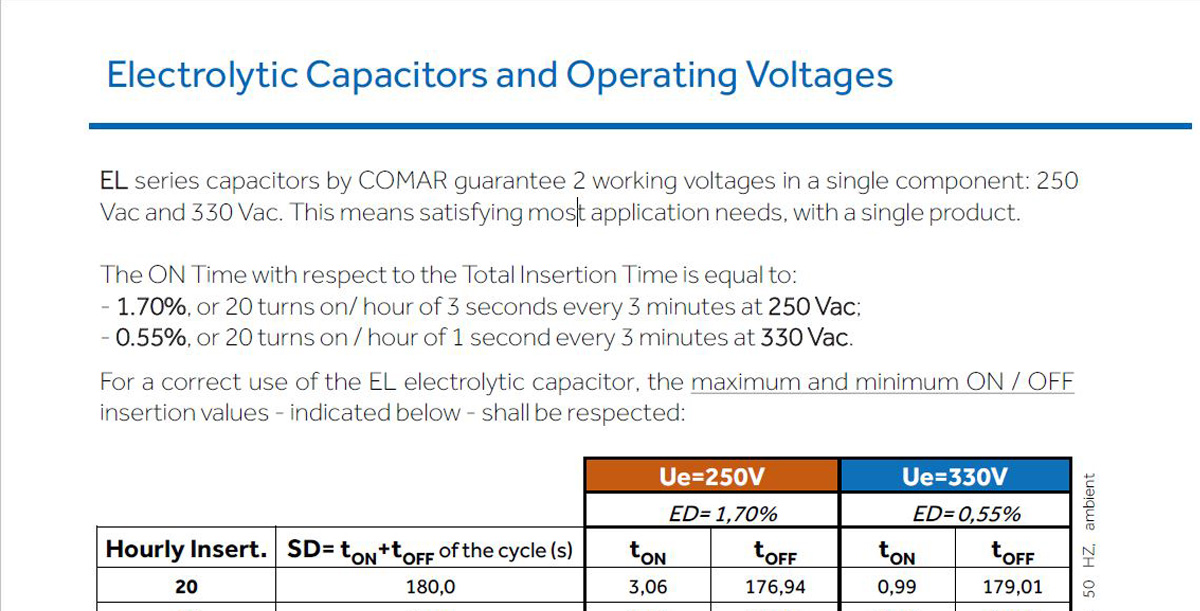

In fact, with the advent of electronic equipment, the compensation of an electrical network requires the knowledge of specific solutions, in particular as regards the harmonic pollution rate in current and voltage.

Installation of technically incorrect or unsuitable capacitor banks in an electrical network, without knowing the most modern protection systems, can cause terrible damage. Only an experienced manufacturer, therefore, knows the technologies necessary to create a self-protected power factor correction equipment (able to put itself in a state of security if the working conditions are too burdensome).

A capacitor bank is essentially an energy warehouse and if this warehouse is not well managed, it can explode, catch fire and cause damage to things or people.

For this reason, instead of trying to produce a power factor correction panel independently, we initially recommend a more careful approach, in particular, aimed at protecting the image and reputation of the client company.

As already mentioned, the construction of capacitor banks requires experience: if in addition to capacitors it is also necessary to use blocking reactors, it is mandatory to know the dynamics that regulate the saturation phenomenon of a reactor with winding on an iron core.

This is why companies that specialize in providing professional solutions (e.g. auditing, electrical measurement campaigns, etc.), as well as electrical panels assemblers, usually avoid trying out “homemade“ solutions when it comes to PFC. An experienced supplier like COMAR, indeed, is able to take into account different critical issues during the design of the capacitor banks. Please consider the following case:

- How to size a capacitor bank in the presence of a harmonic distortion rate in the current (THDI) of 120% and in voltage (THDU) of 20%?

- What tuning frequency should the blocking reactor (= inductance) have and what should its linearity be?

- In the event of an overload (in voltage, current or excessive harmonic contamination), what should be the technical countermeasures that must be taken to prevent the explosion ofthe capacitor bank?

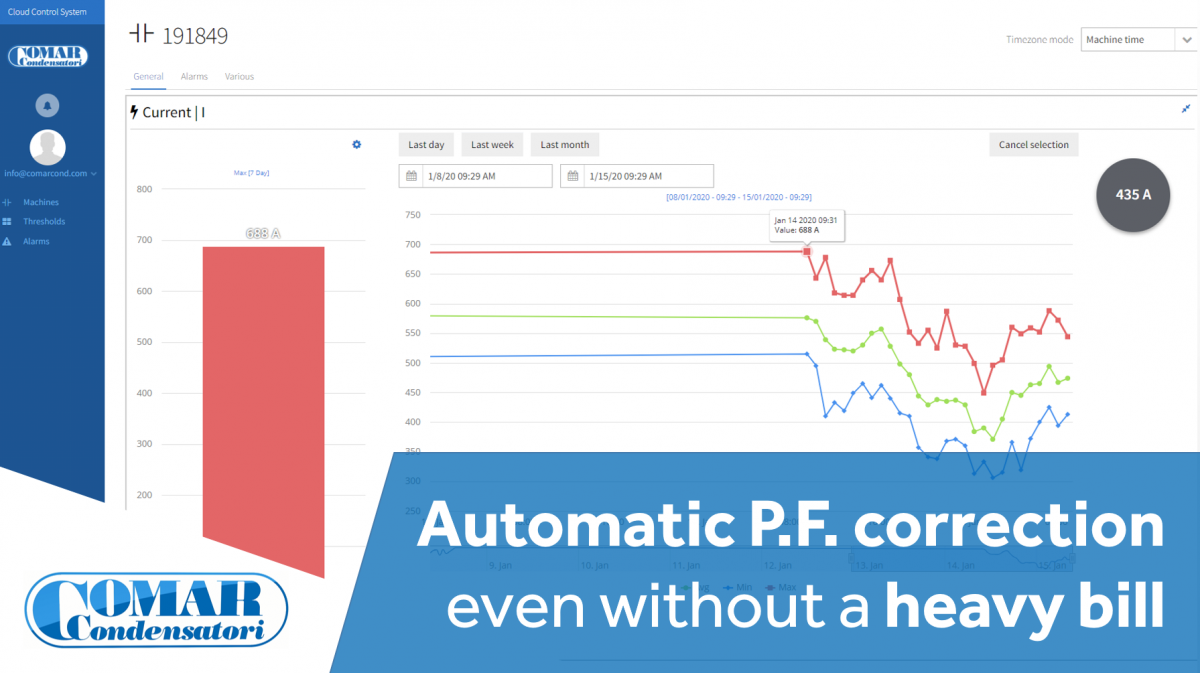

- What should be the reaction time of the automatic PFC equipment to compensate forthe loadwell?

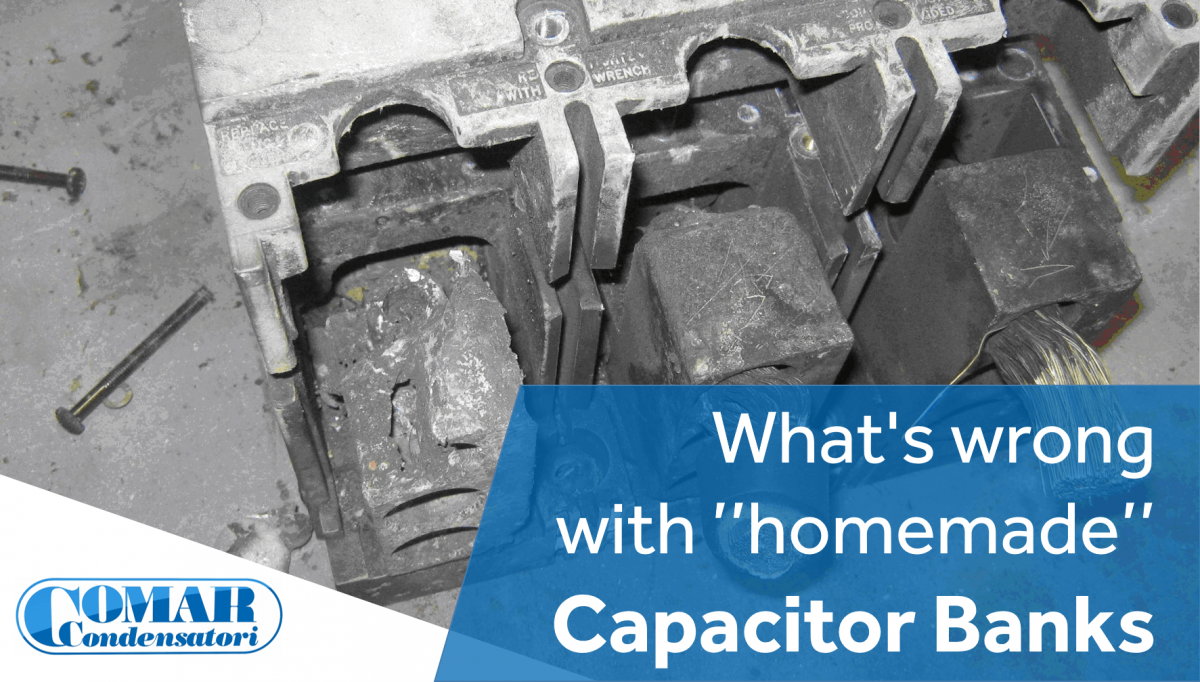

As it is easy to understand, this is not a job that can be improvised. Below we show the picture of an automatic capacitor bank made by a French assembler.

The latter decided not to buy a COMAR equipment or our capacitors (famous for their anti-burst device and discharge resistance). Almost as a challenge and without listening to our advice, he decided to build the equipment on his own,thus believing it would save money.

However, the capacitor banks he built caught fire shortly after commissioning, causing serious damages that led him to pay huge compensation to the enraged customer!